From discovery to decommissioning, we’re your life-of-field subsea technology provider

Our company is at work in almost every oilfield, supporting almost every phase of its development – safer, cleaner and more efficiently than ever before.

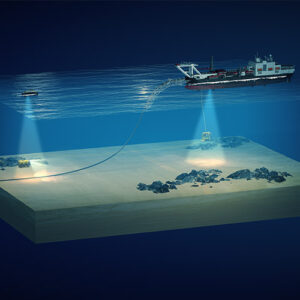

Exploration

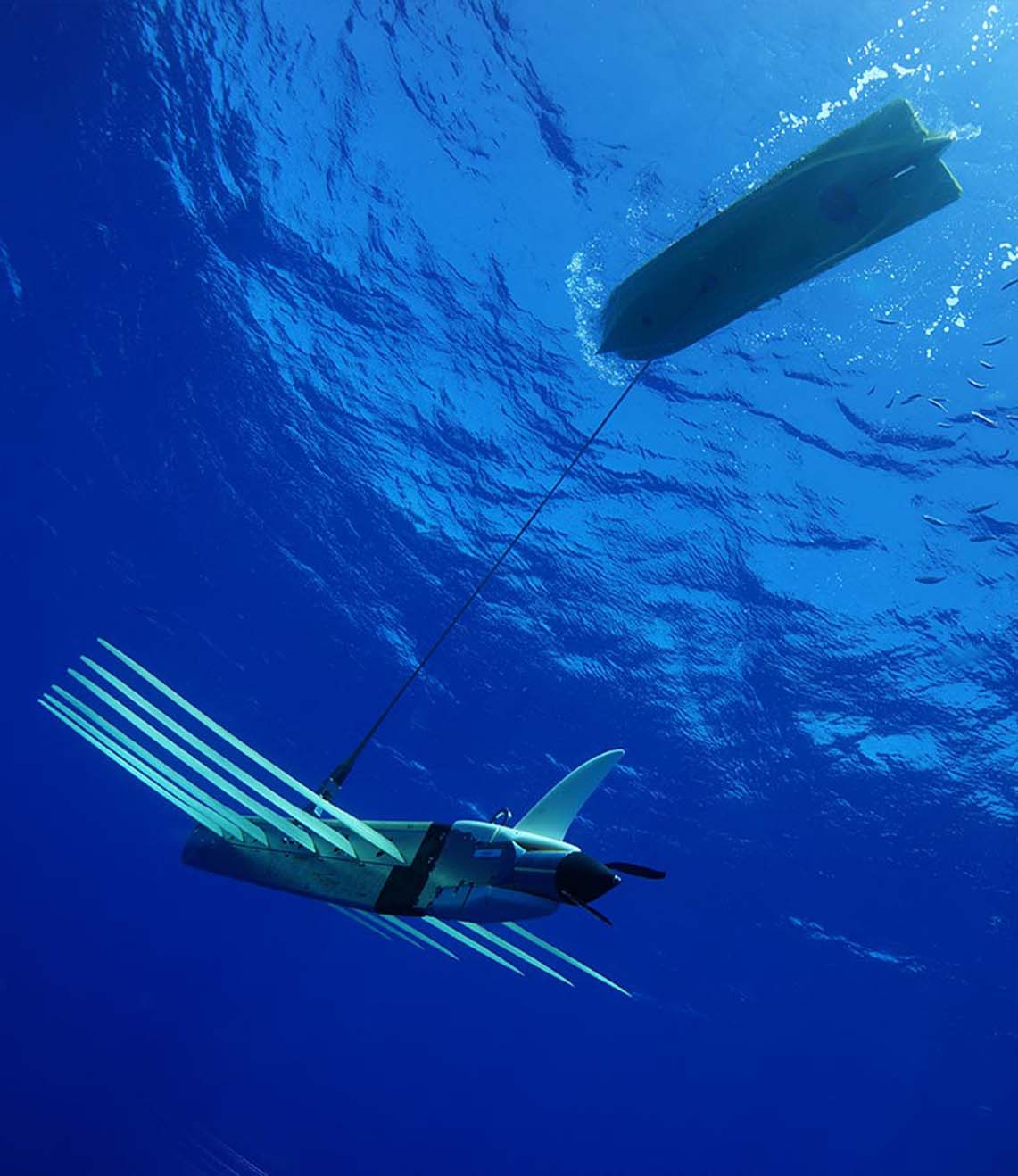

We’re able to help reduce the cost of seismic data acquisition with solutions designed to simultaneously position thousands of cabled hydrophones, or track, command, and communicate with swarms of flying seabed nodes.

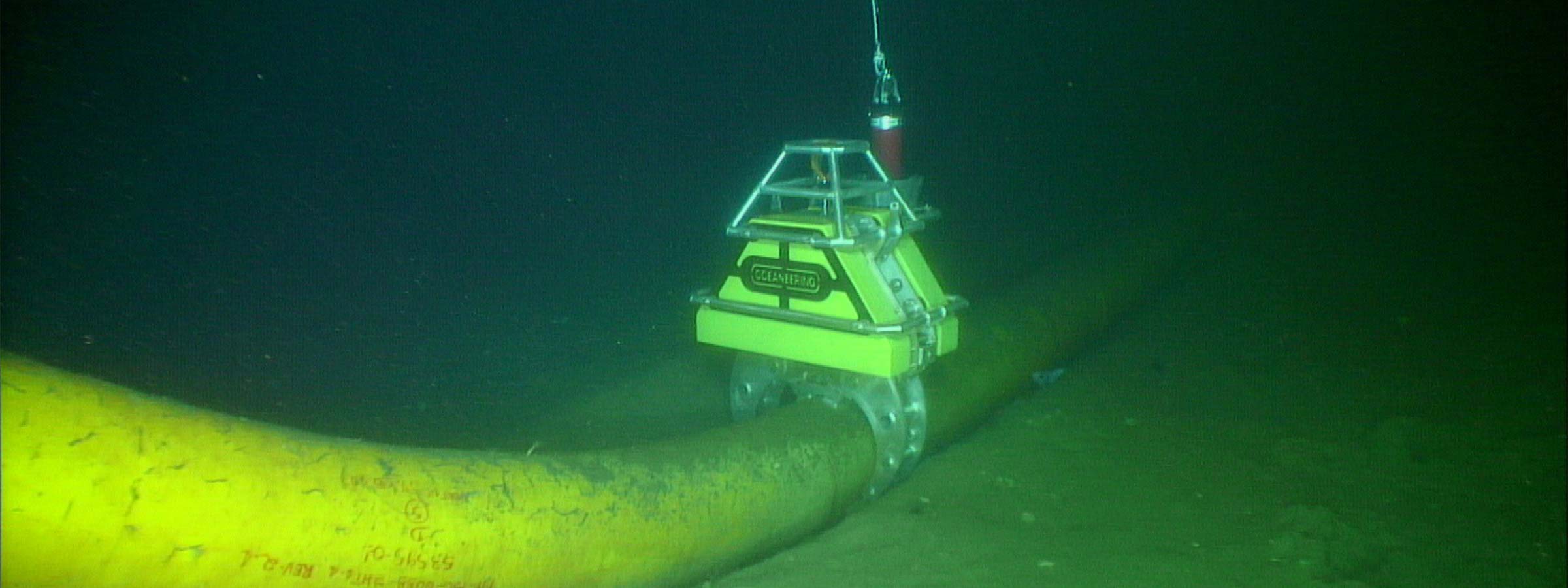

Survey and inspection

Our acoustic-inertial technology portfolio offers simplified solutions for site surveys and inspections utilising remote and autonomous vehicles, conventional vessels and uncrewed surface vessels – solutions that are helping to re-write the survey rulebook.

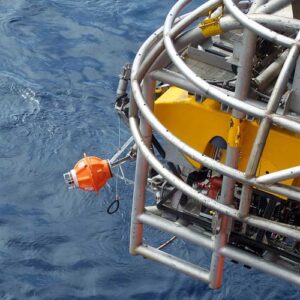

Construction

Managing risk, reducing complexity, reducing time offshore. Our trusted techniques and systems support your goals for installing and commissioning subsea structures in any water depth, with less equipment, in less time and with less people.

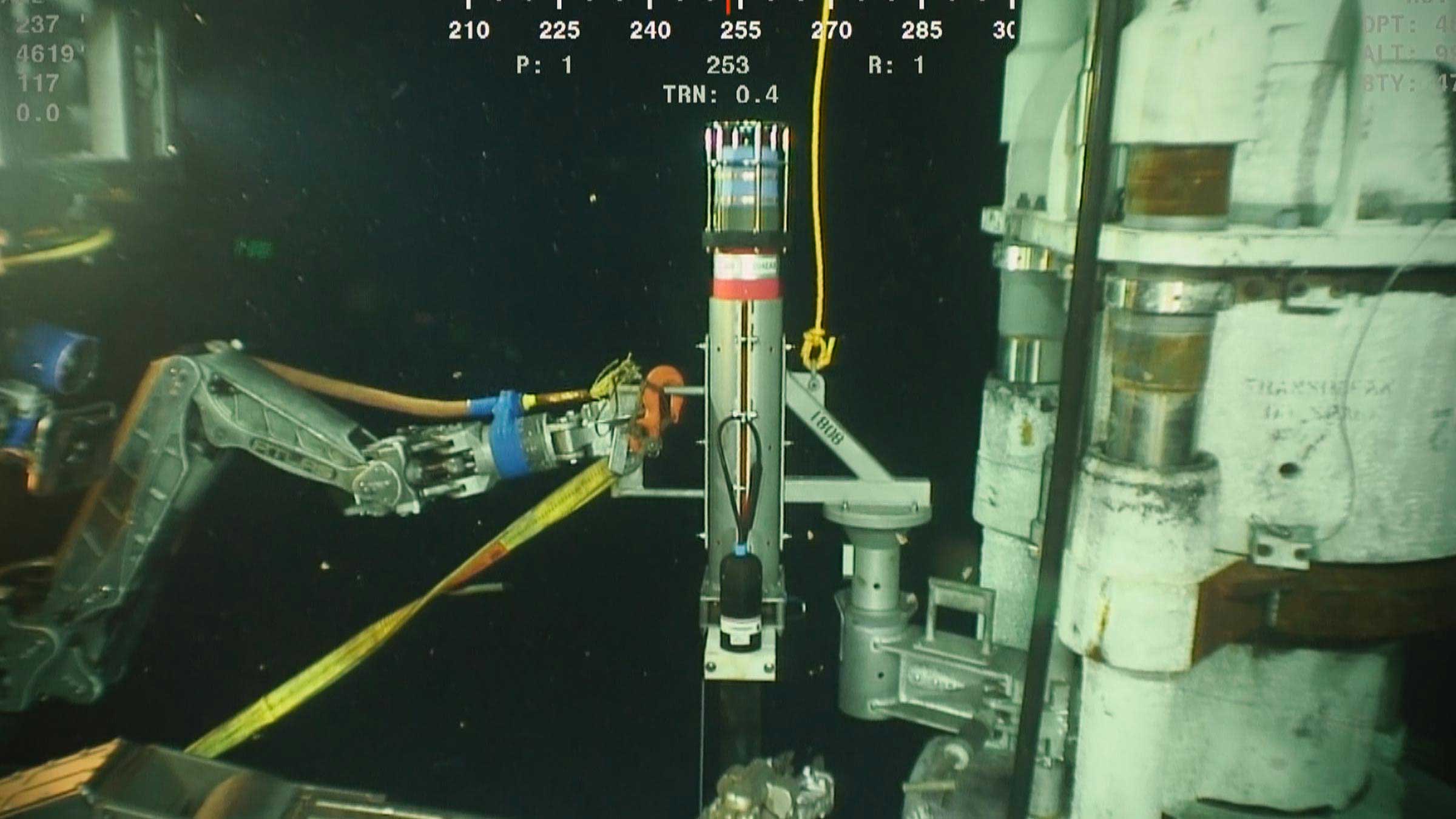

Asset integrity

Our expertise encompasses autonomous networks of seabed sensors monitoring structural vibration and safety critical control systems mounted on BOPs, to the detection, classification and localisation of hydrocarbon leaks, mooring line and riser monitoring. It’s also the ideal solution for monitoring your offshore CCS ensuring carbon remains captured.

Surveillance

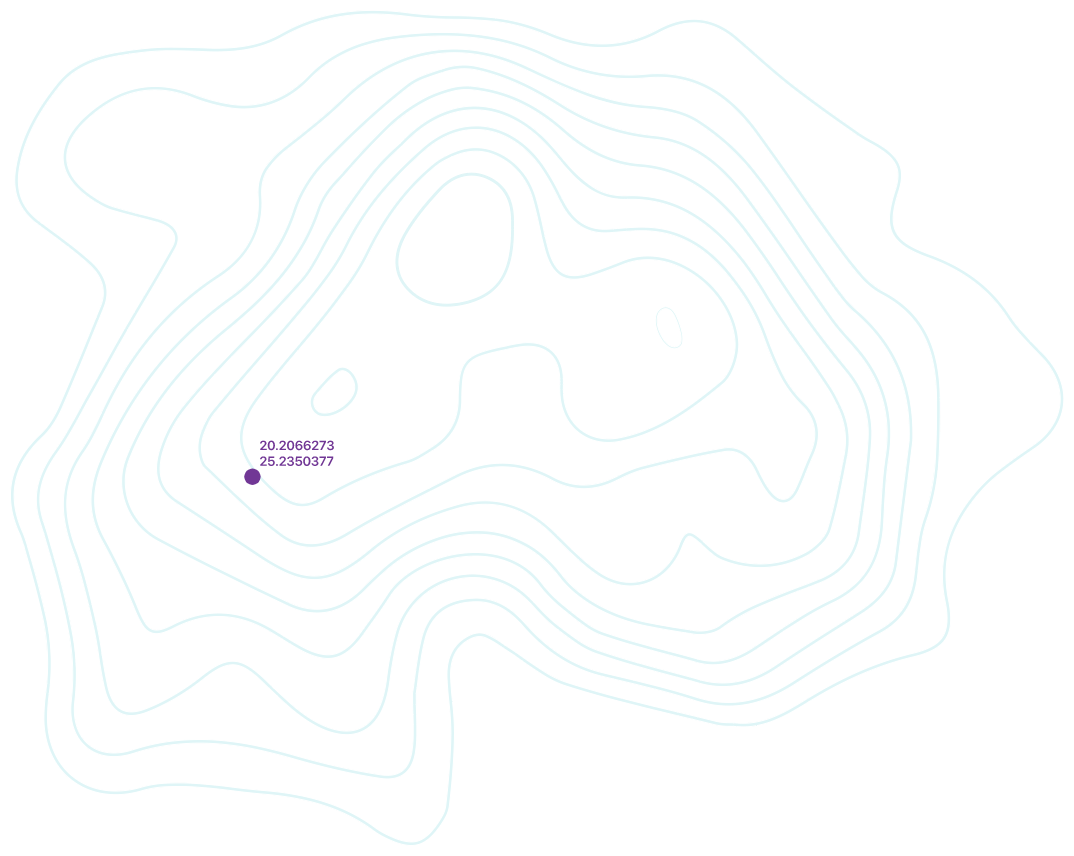

Permanent seafloor surveillance, unpinned by our award-winning technology, unlock new insight into offshore reservoirs by identifying ways to optimise production, de-risk well placement and detect early signs of geo-hazards.

Vessel systems, including uncrewed

We’re able to extend the operational capability of your vessel, reduce downtime and enable your team to remotely support offshore operations from onshore. And with solutions for uncrewed vessels, we can deliver your data faster, safer and more sustainably than ever before.

Navigate, track, measure, monitor, release, observe. Your applications, our innovations

Sustainable, safe, efficient

Carbon neutral by 2025

We’re aiming to become carbon neutral by the end of 2025, an ambitious goal which covers direct and indirect emissions, including those associated with manufacturing as well as supply chain activities, from our UK sites and operations. It cements our long-term commitment to being an environmentally responsible and sustainable commercial partner to do business with.

Remote, over-the-horizon, uncrewed

Operating remotely and managing projects with less people at sea is more important than ever, so we’ve created new products and services to be by your side, event when we can’t be. Innovations such as ROAM which connects our experts to your team during live operations, and a fully managed data harvesting service using USVs.

Efficient, smart, quick

Our field-proven, low-risk technology is designed to let you achieve more with less hardware deployed on the seabed, efficiencies that save not just hours days but days of vessel time – and all without compromising the specifications set for your project.

Energy case studies

Energy

Remote Advances; Operational Advantages

A joint operation between Sonardyne and Subsea 7 has helped to de-risk technology adoption on BP’s Mad Dog Phase 2 development by allowing 24-hour remote access to offshore survey systems for onshore staff, de-risking the use of new technology, reducing project overheads, and paving the way for new ways of working in the future.

Client: Subsea 7

Energy

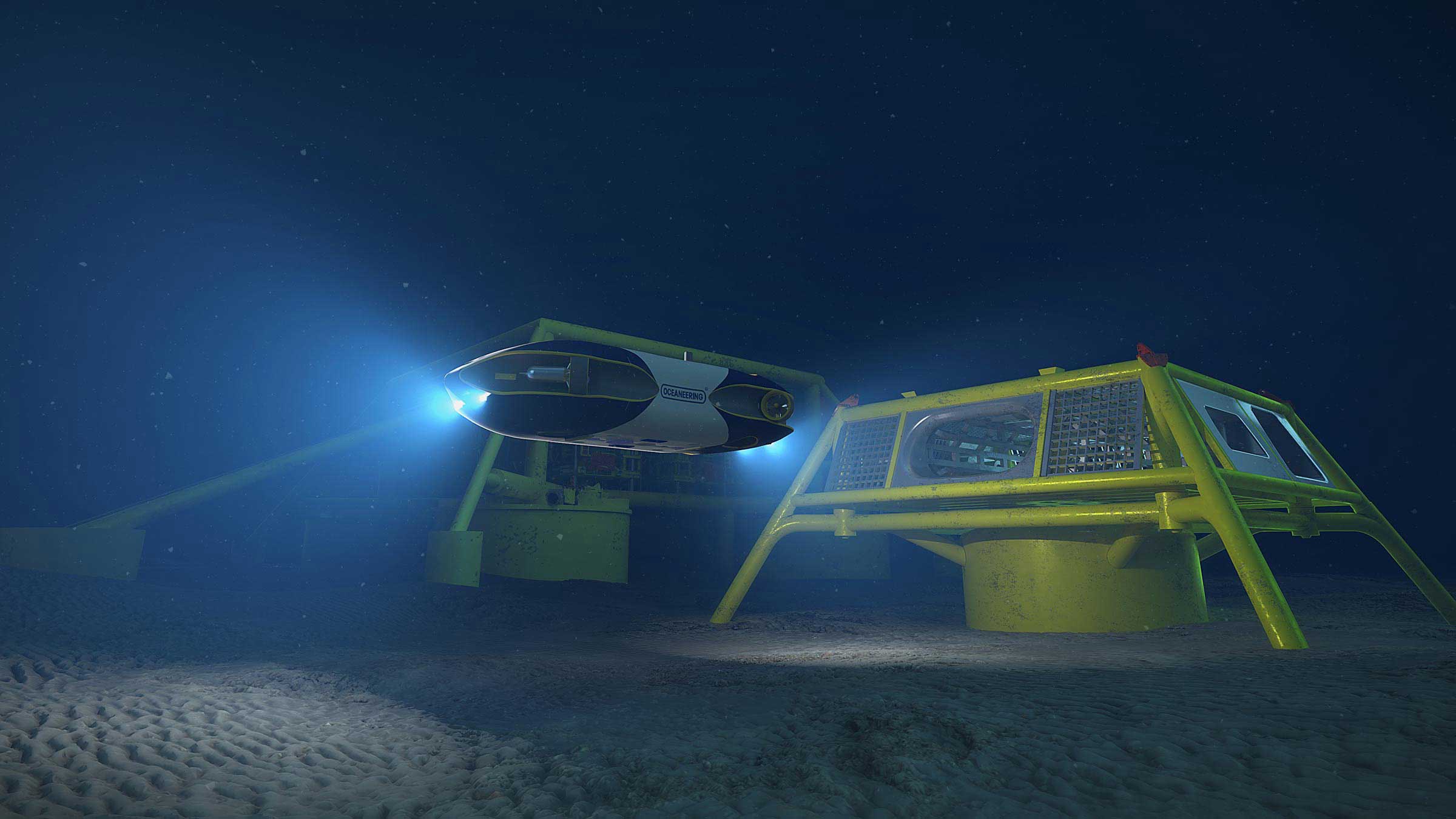

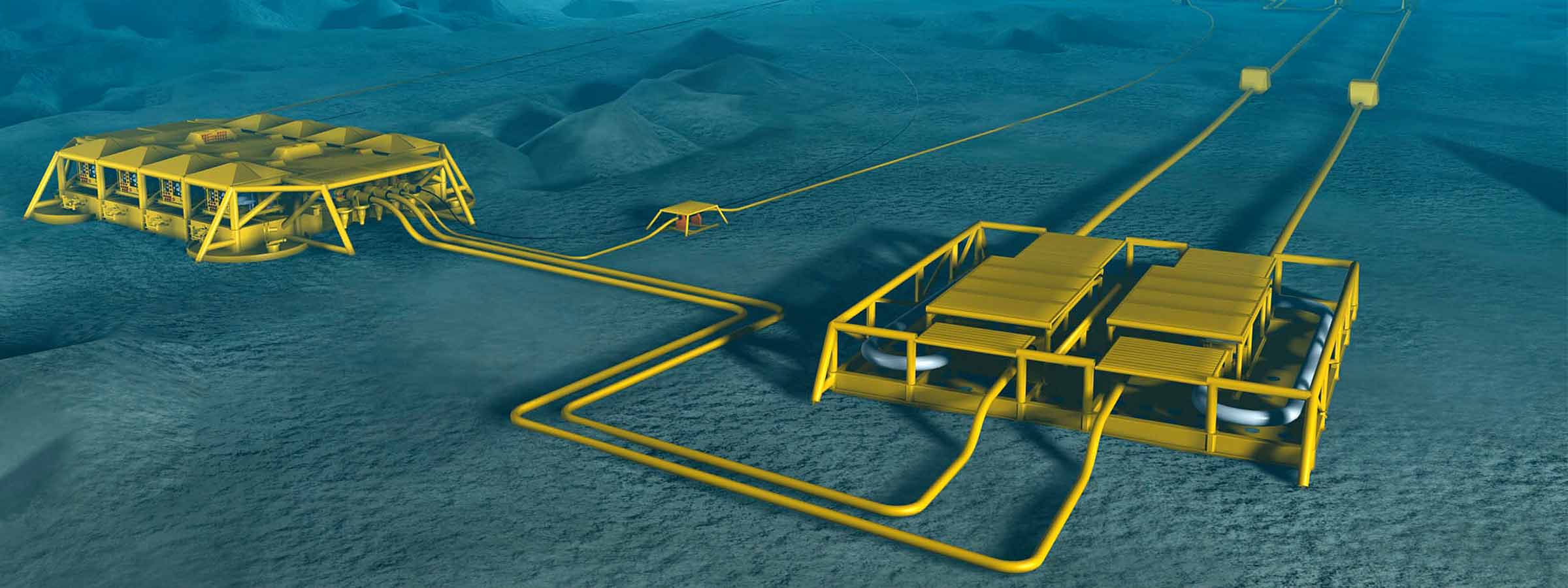

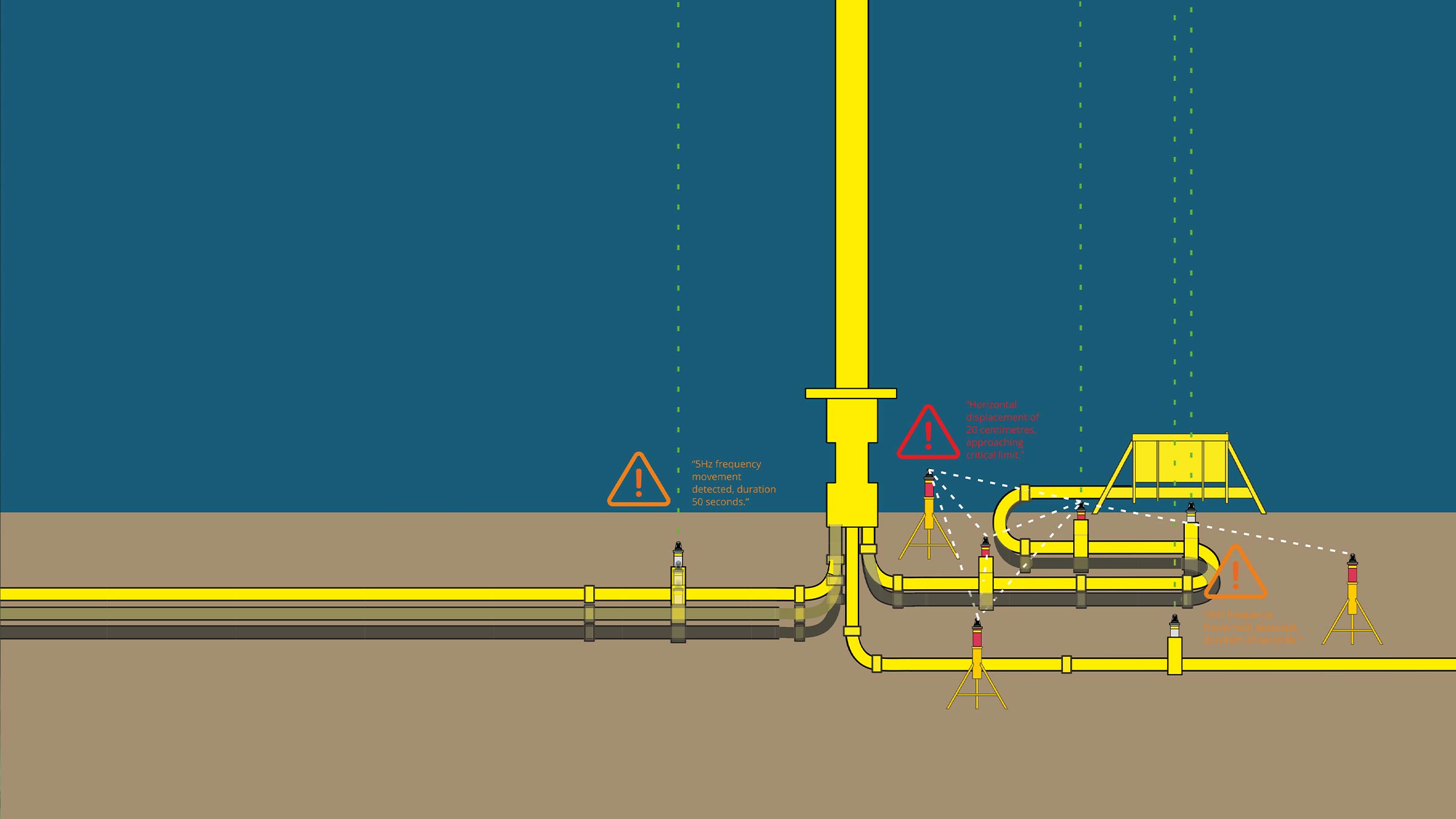

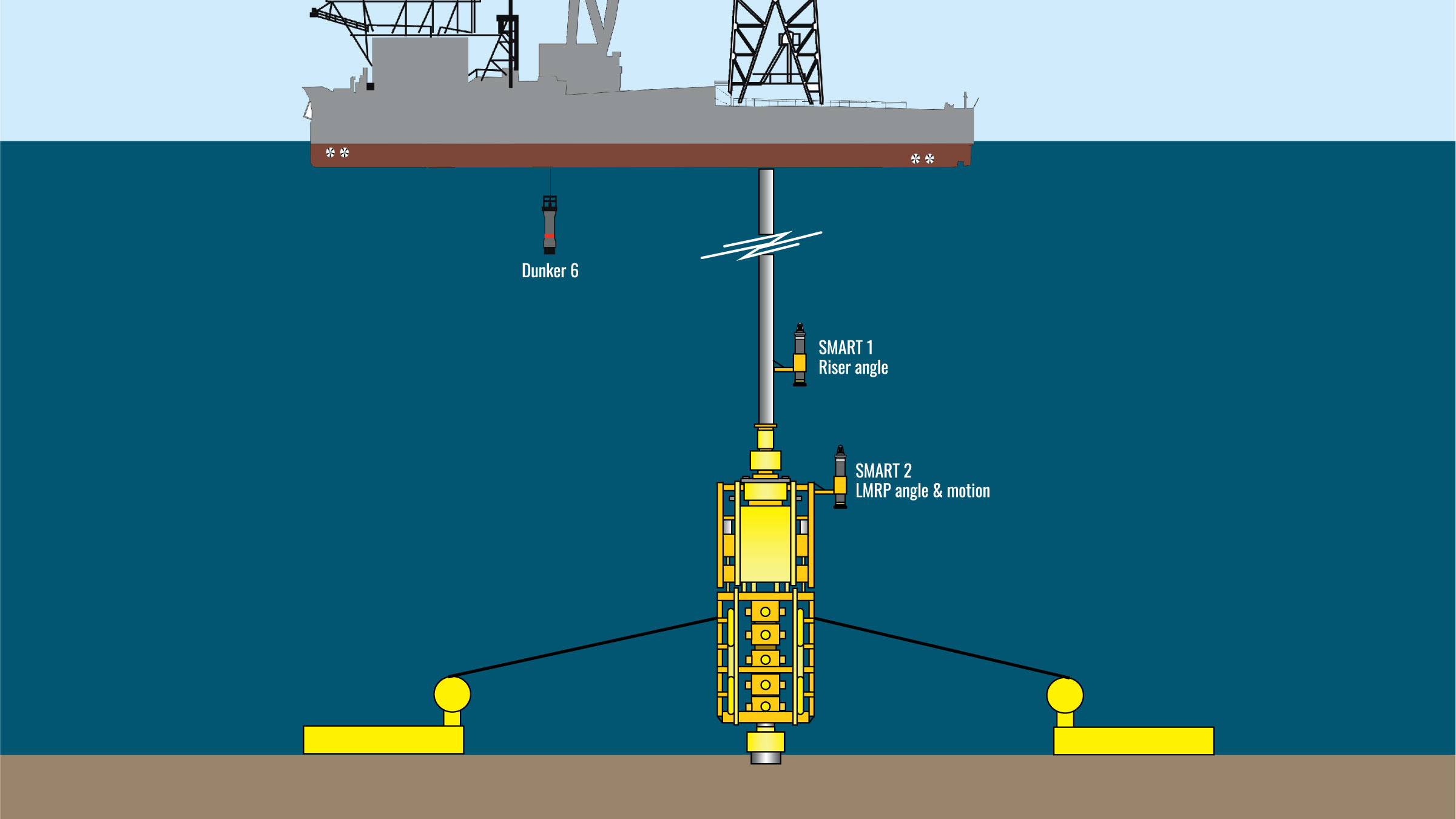

Keeping production flowing by understanding subsea asset movement – wirelessly

Read if you’re interested in flowline, spool piece or riser monitoring, slugging, walking or creeping of subsea assets, and how our SMART and AMT technologies helped Oceaneering and their own client keep production flowing.

Client: Oceaneering Inc.

Energy

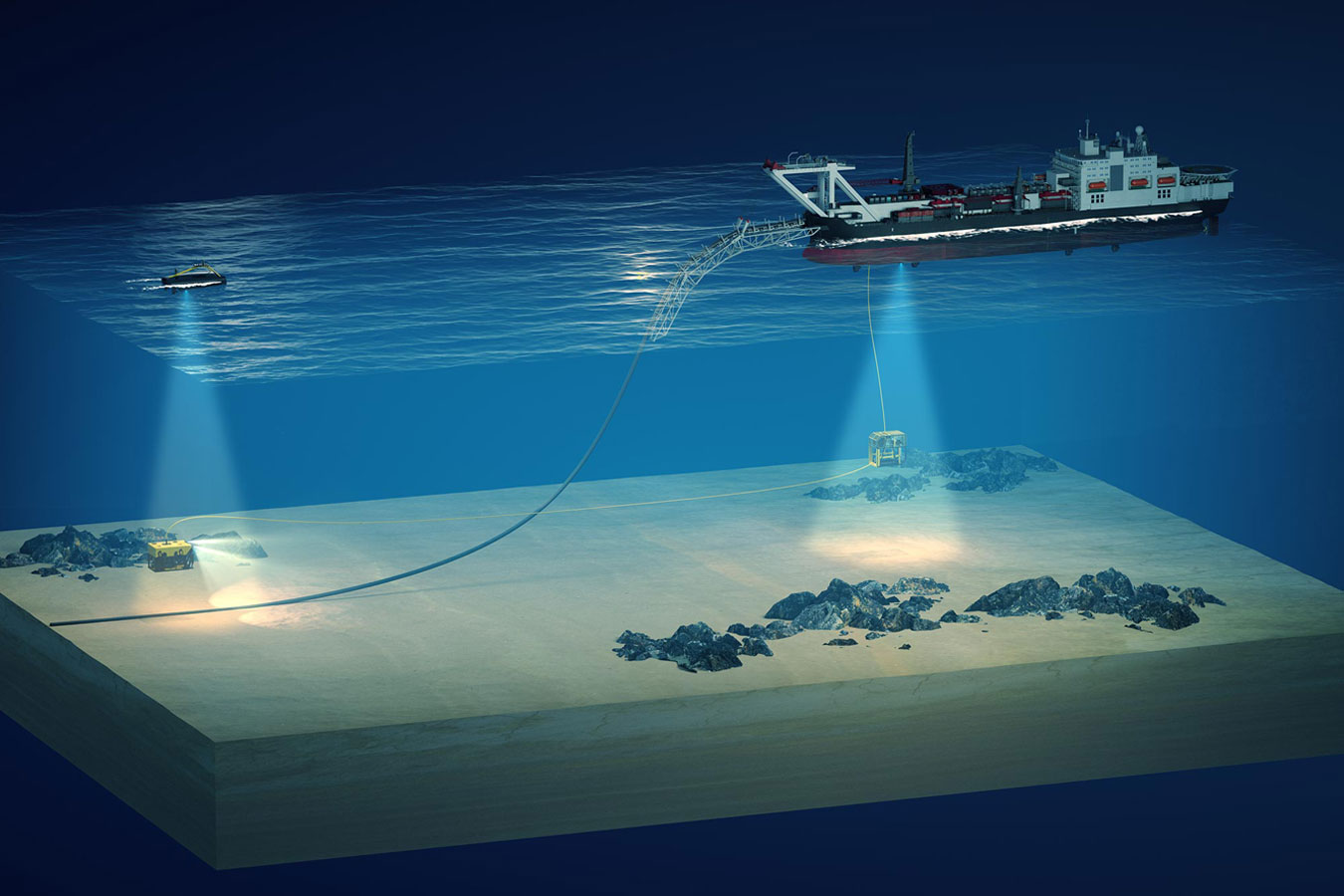

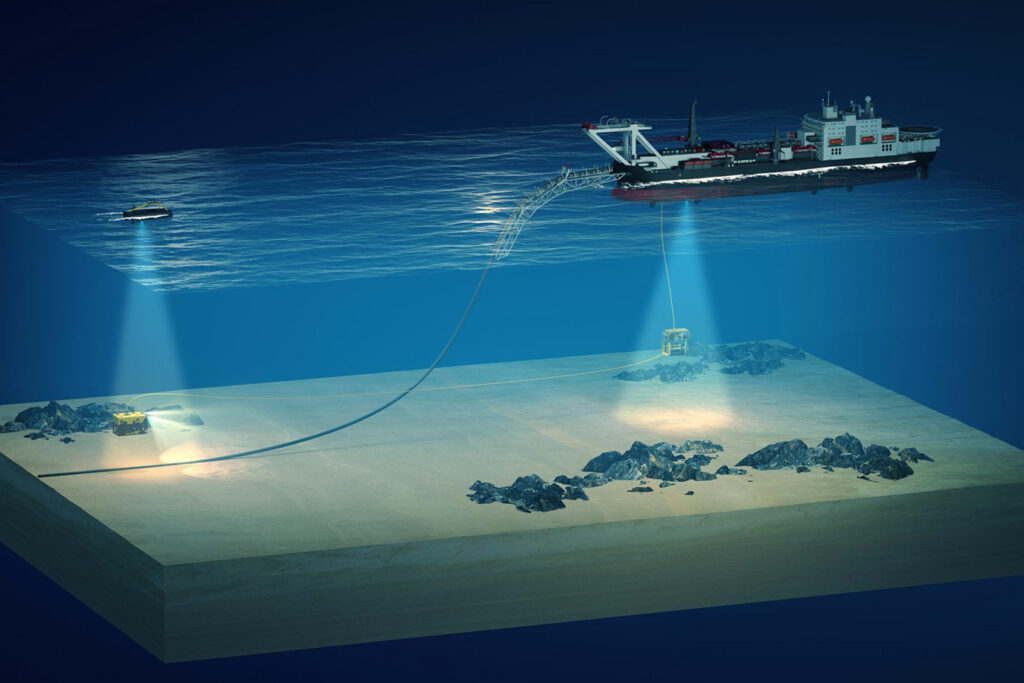

Subsidence monitoring at offshore oilfields

Read if you’re interested in subsidence monitoring at offshore oilfields, and how our long endurance remote and autonomous instruments, working together with an uncrewed surface vessel, helped Norkse Shell measure seabed movement across the giant Ormen Lange gas field.

Client: Norske Shell

Energy

Deepwater structure installation made easy

Read if you’re interested making subsea developments safer, cleaner and more efficient than ever before, and how our GyroCompatt helped China Offshore Fugro Geosolutions achieve its project goals

Client: China Offshore Fugro Geosolutions

Energy

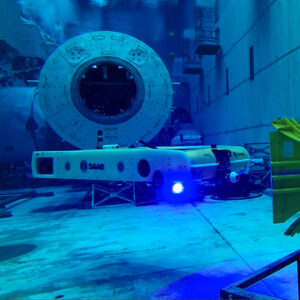

Long ROV excursions, high elevation tracking, noisy waters – not a problem

ROV pipeline inspections in shallow water – with long excursions and high elevation tracking requirements – can pose major challenges for even the best USBL systems. With SPRINT-Nav in the mix, it’s no longer an issue. Tavis Letherby, Survey/ROV Manager at CCC (Underwater Engineering), explains.

Client: CCC

Ocean Science

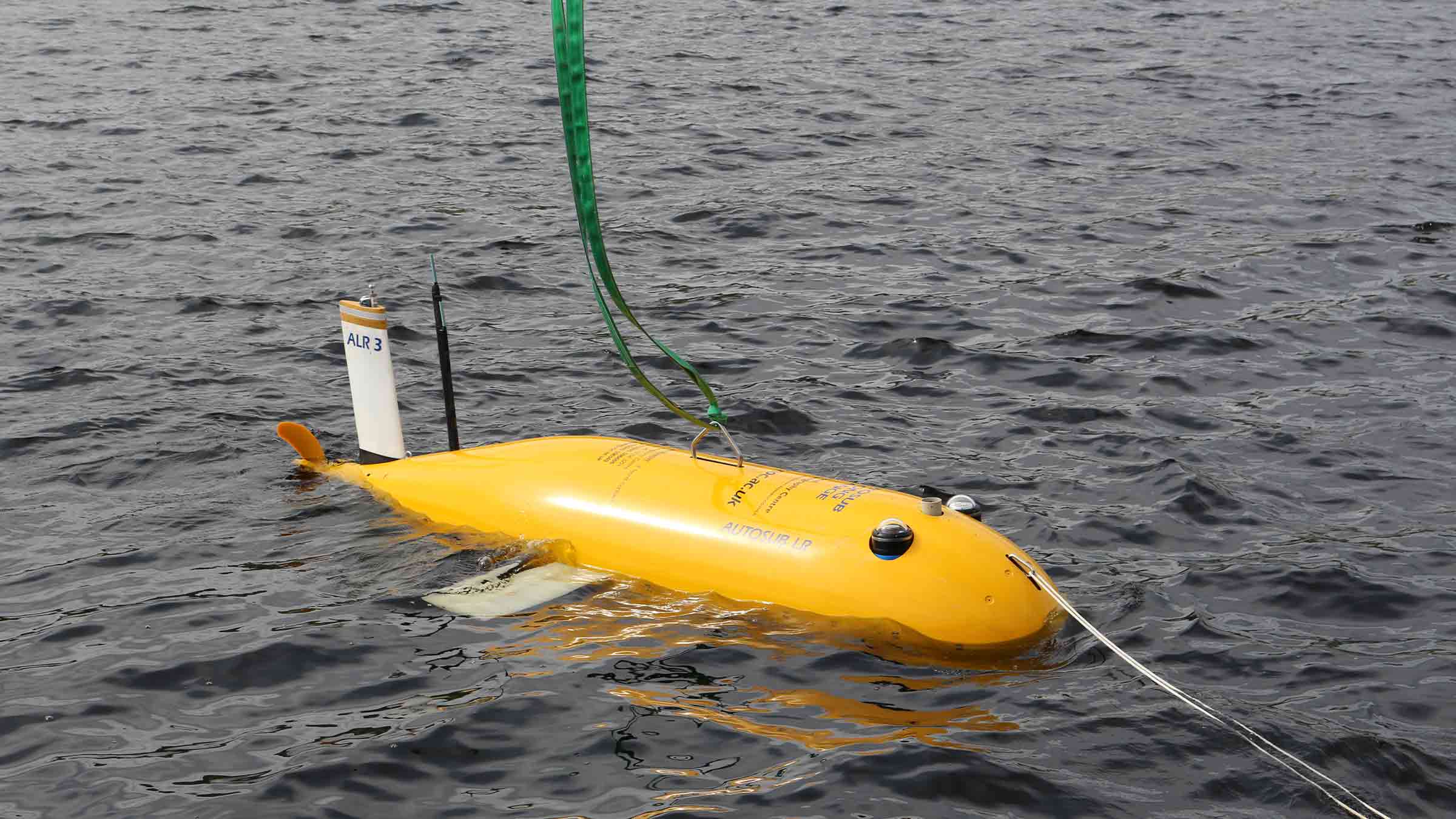

Extending the limits of autonomous systems

Improving the endurance and navigational precision of underwater autonomous systems, while also reducing costs, could provide disruptive capability in the subsea monitoring and inspection space. Geraint West, Ocean Science Head of Market, explores the challenges and solutions.

Client: National Oceanography Centre (NOC) and L3Harris ASV

Energy

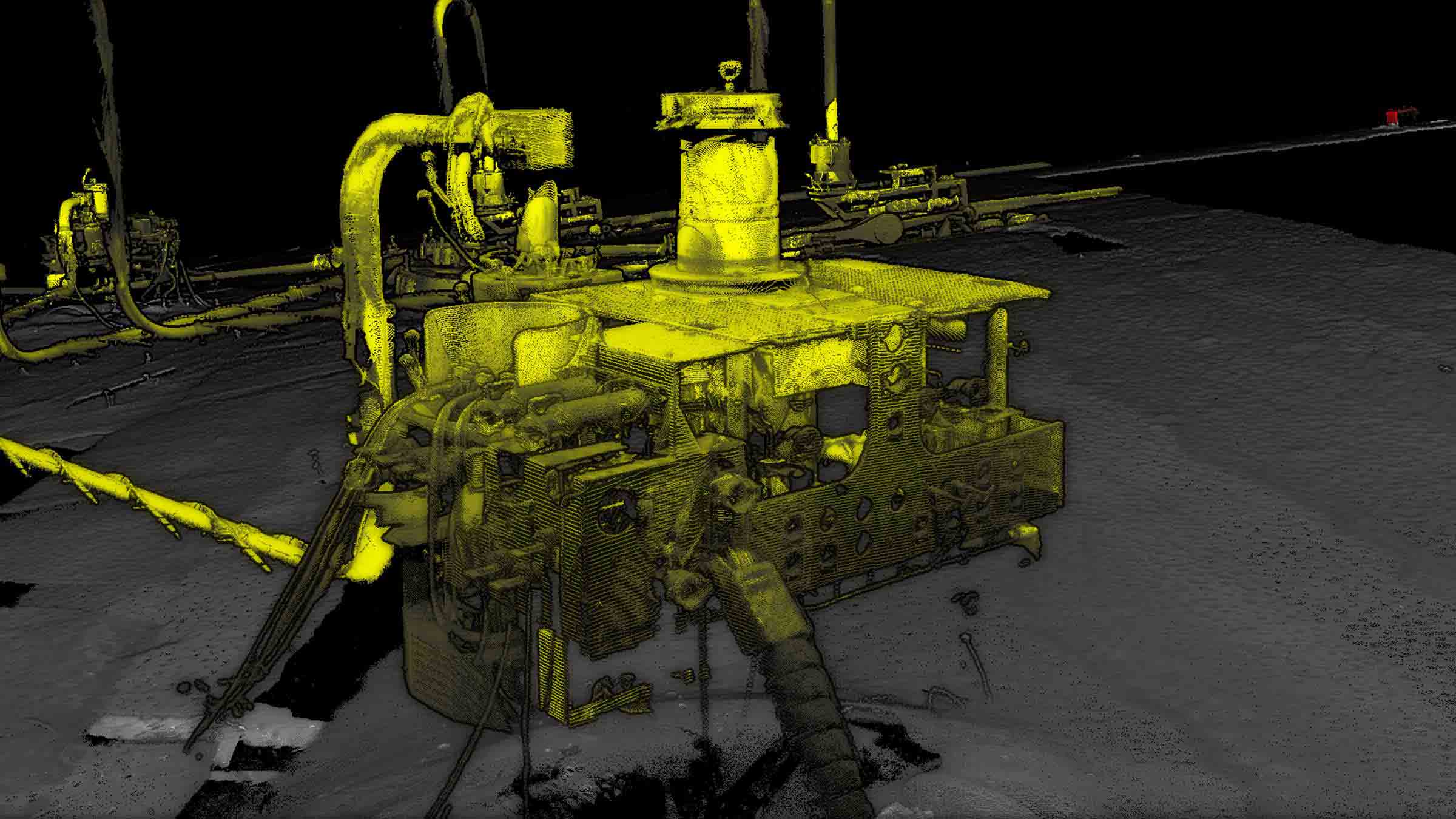

Deepwater data analytics – asset monitoring at the edge

Thousands of kilometres of pipeline, flowline, and interconnecting spool pieces are installed on the world’s sea and ocean floors. Monitoring and maintaining these vast networks of pipes can be challenging. Explore how Oceaneering provided the analytics they needed to monitor these pipes using our SMART technology.

Client: Oceaneering

Ocean Science

Ranger 2 – it’s anything but standard.

With our Ranger 2 permanently installed onboard the RRS James Cook, a team from the UK’s National Oceanography Centre (NOC) was able to significantly reduce the uncertainty around the position of their autonomous underwater vehicle (AUV).

Client: National Oceanographic Centre

Energy

Seismic operations in the transition zone

We’re doing so much more using uncrewed surface vessel (USV) systems, right through the life cycle of exploration and production operations. It starts with the support of seismic data acquisition, using our Transition Zone Transceiver (TZ Transceiver).

Client: Maritime Robotics

Energy

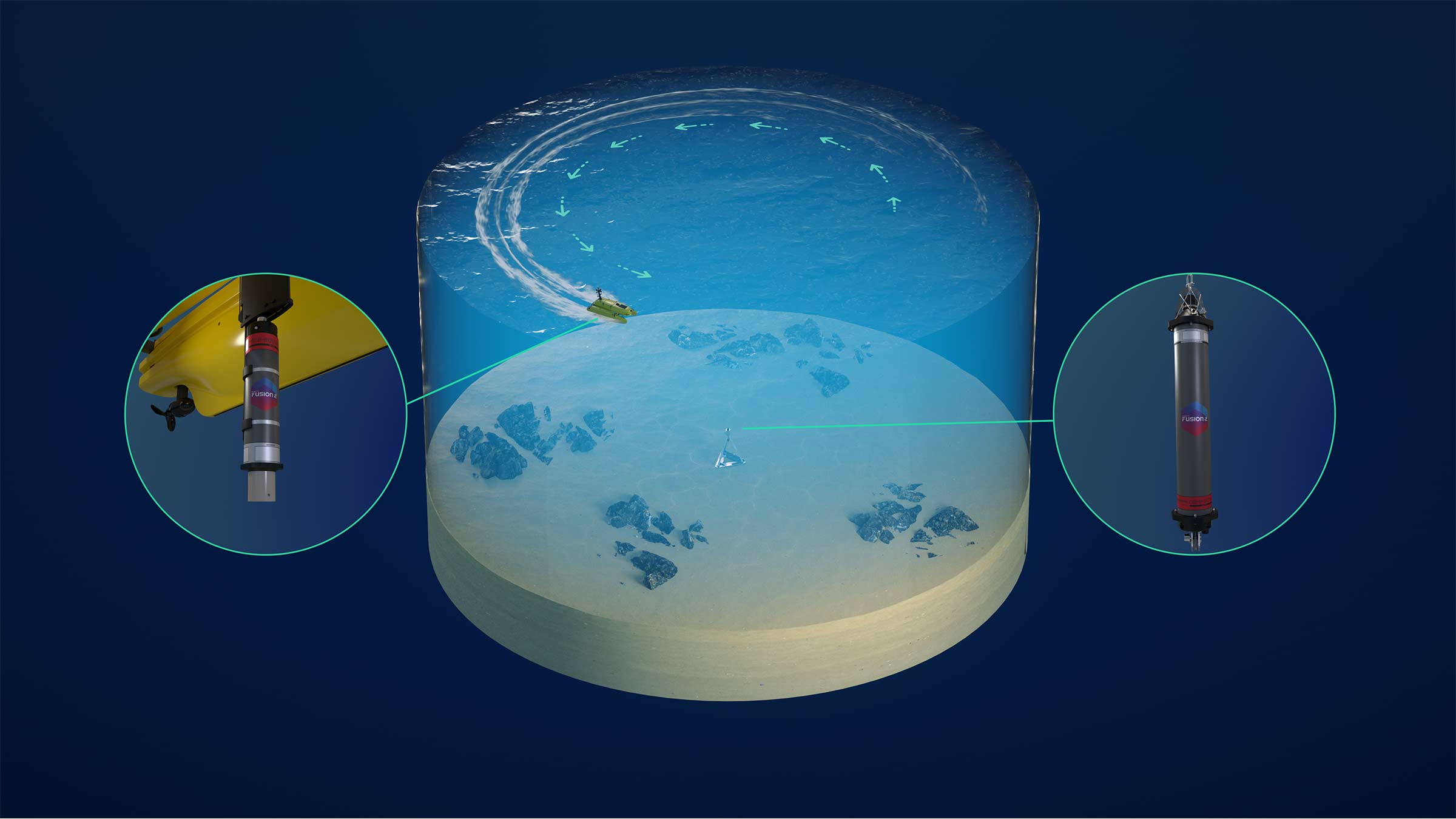

Rewriting the subsea survey rules

Fusion 2 is not just simplifying offshore survey operations, it’s changing how people operate – for the better. Mike Clark, Global Survey Manager, i-Tech 7, told Baseline about their route to demonstrating reductions in offshore vessel schedules for Subsea 7’s deepwater field development projects using the real-time SLAM capability in Fusion 2.

Client: i-Tech 7

Energy

Trendsetter Vulcan Offshore uses a SMART solution to monitoring wellhead fatigue

A reduction in subsea wellhead fatigue life was prevented through the use of a BOP Wellhead Fatigue Mitigation System supported by our Subsea Monitoring, Analysis and Reporting Technology (SMART). By enabling drilling operations using larger BOPs on older wellheads, operators are able to extend production and field life cost-effectively.

Client: Trendsetter Vulcan Offshore

Energy

6G modems make the connection between data and decisions

Learn how RPS Ocean Science used our modem technology to measure seabed current profile data at the Walker Ridge area in the Gulf of Mexico and wirelessly transmit the observations to the surface for instant analysis.

Client: RPS Ocean Science

Energy

How to optimise carbon storage monitoring with marine robotics

Climate change is driving a ramping up of carbon capture and storage (CCS) projects globally, as countries work to reduce their emissions. There’s also more focus on how to make sure the stuff stays stored in the ground. Read on to hear about our involvement.

Partners: Fugro, National Oceanography Centre (NOC), British Geological Survey (BGS) and Plymouth Marine Laboratory (PML)

Energy

Using a hammer to crack a nut? Try using a USV instead

USVs are no longer a niche tool used within defence, they’re now regularly patrolling our oceans, gathering hydrographic and oceanographic data. Is it time that they were also used to support smarter, cleaner and more cost-effective offshore construction operations? Ed Moller, Head of Energy, thinks so.

Engineering the future of oilfield technology for over 50 years

Our story began with a pioneering vision to make the future of working underwater better than the past.

This vision still guides our company today; a company that is 300 people strong in six regional locations, a company that puts everything it has into designing, building, testing, installing and supporting ground-breaking products and services for energy; a business that takes ownership, does the right thing and consistently delivers on the promises we make.

Our future story is safe, sustainable and economic solutions for offshore oilfield development. Partner with us and be part of the next chapter.